cpc Studio: motion control software

Maximum control with cpc Studio

cpc Studio is an integrated development environment that transforms industrial computers into powerful PLCs with real-time control. Say goodbye to hardware restrictions and tailor system projects with flexibility.

Benefits of cpc Studio

cpc Studio provides cost-effective libraries, precise motion control and supports a variety of communication protocols, such as EtherCAT and Modbus TCP. Our user-friendly software is the ideal choice to elevate machine-building capabilities.

Turn your computer into a PLC for free and reliable motion control

Benefit from the power of cpc Studio with these key advantages:

- Diversified intuitive teaching functions

- Zero gravity mode

- Collision detection

- PLC open motion control function blocks

- Ethercat and modbus support

- IT and OT convergence

- OPC UA communication

cpc Robot

Introducing cpc’s miniature 6-axis robotic arm series: DB0 high-precision robot and S0 Cobot.

For OEMs delivering cutting-edge machines, our robots offer agility, smart learning, energy-saving and adaptability, revolutionizing machine designs.

Say goodbye to rigid setups and hello to flexible, efficient solutions for your clients.

Request a demo

Are you ready to experience our innovative robotic systems firsthand? Request a demo and discover how they can transform your operations. Fill out the form below and our team will contact you.

cpc: Excellence in motion

Empower machines with cpc’s linear drives & components. Unmatched precision, unwavering quality and competitive pricing for enhanced machine performance and efficiency.

cpc Studio – industries & applications

Explore how cpc Studio motion control software is transforming various industries, providing machine builders with precise and innovative automation solutions.

Medical

- (Micro) surgery

- Diagnostics

- Lab automation

- Telemedicine

- Sterilization

Packaging & transport

- Materials handling

- Picking & placing

- Palletizing

- Package sealing

- Quality inspection

Machine tools

- Precision assembly

- Quality control

- Electronics assembly

- Scanning /glueing

- Tool changing

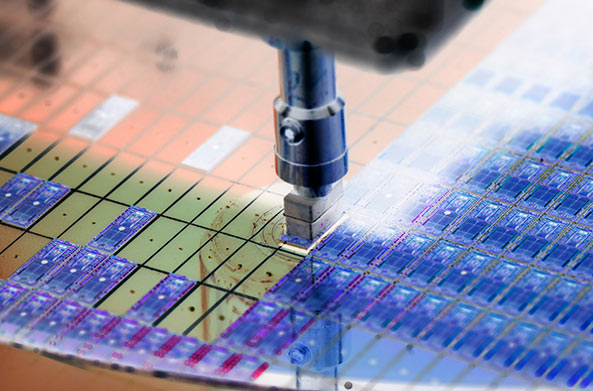

Semiconductors

- Microchip assembly

- Inspection

- Cleanroom operations

- Electroplating

- Etching